Concept · Co-Development Opportunity

Structural Digital Twin for Cargo Operations – Seeking Development Partners

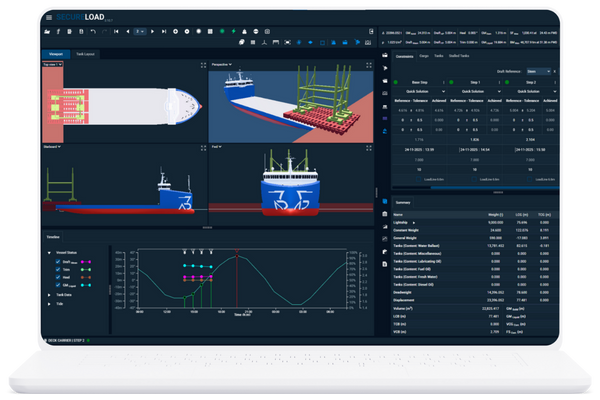

Structural Digital Twin is a next-generation capability we’re building on top of SecureLoad: vessel-specific structural models connected to real load cases and, over time, sensor data.

The goal is to move from “case-by-case” strength checks to a living view of how cargo operations affect a vessel’s structure over its life. We’re looking for technology and engineering partners to co-develop this.

From Idea to Jointly-Built Product

Structural Digital Twin is not a generally available module today – it’s an R&D track aimed at turning SecureLoad’s cargo engineering core into a structural decision-support layer.

Instead of isolated checks, the goal is to accumulate real load cases over time and turn them into insight on strength, fatigue and utilisation across a vessel’s life.

Built on SecureLoad’s Physics Core

Focused on Real Operational Questions

Shaped with Strategic Partners

What We Want to Solve Together

Use Case 1

Turning Load Cases into Structural Insight

- Connect SecureLoad’s loading computer and planning outputs into a structural model that can “remember” what the vessel experiences over time.

- Link real loading cases and voyages to a vessel-specific structural model.

- Understand cumulative utilisation, fatigue “hot spots” and emerging risk trends on critical members.

- Package this insight in a way operators, class and engineering teams can act on – beyond one-off reports.

Use Case 2

Enriching Sensor & Automation Data

- Go beyond raw sensor values by tying them to structure, cargo and operations.

- Combine sensor feeds (motions, strains, tank data and related signals) with structural models and real load cases.

- Build smarter alerting and decision-support, not just threshold alarms.

- Offer differentiated services on top of existing hardware and automation footprints.

Use Case 3

New Services for Advanced Fleets

- Turn structural insight into services that change how advanced fleets are run and marketed.

- Support life-extension decisions, trade changes and risk-based inspection strategies with better evidence.

- Help owners quantify structural impact of different trades, cargo mixes and project campaigns.

- Co-sell a combined software + expertise offering to operators who want structural intelligence as an ongoing service, not a one-off study.

A Structural Layer on Top of SecureLoad

Inputs

Load cases and conditions from SecureLoad (Loading Computer, 3D Stowage Planner and Fleet Cargo Planner) become structured inputs to the twin.

Where available, sensor and automation data (motions, strains, tank data, etc.) can be added to link real-world behaviour to the structural model.

Structural Engine

Partner-defined structural models, FEA and assessment methods sit inside a shared framework.

SecureLoad supplies the operational context; partners bring the structural science, rules and experience.

Outputs

Dashboards, reports and APIs turn structural insight into something usable by operators, class and engineering teams.

Partners can package and take these outputs to market as part of their own digital and advisory offerings.

Co-Development Pilot with Selected Partners

What We Bring

SecureLoad Platform & Vessel Geometry

A mature cargo-engineering platform with vessel models, load cases and workflows already in daily use.

Product & Engineering Team

Teams to build integrations, data flows and UX that connect structural models into real planning and loading work.

Route to Market

Access to existing SecureLoad and Admaren customers in bulk, breakbulk, heavy-lift and project trades.

What We’re Looking For

Partner Types

Technology / OEM partners (automation, sensor and systems providers), class / engineering firms, or advanced operators.

Vessels, Data & Expertise

Access to representative vessels, operational data and structural / naval expertise to ground the solution in reality.

Co-Shaping the Product

Willingness to help shape the roadmap, test prototypes in live contexts and define viable commercial models together.

Roadmap – To Be Shaped Together

Phase 1 – Exploration & Prototyping

- Jointly select representative vessels and data sources.

- Build initial structural models and connectors into SecureLoad load cases.

- Validate early visualisations and metrics with partner engineering and operations teams.

Phase 2 – Pilot Deployments

- Run pilots on a limited number of vessels or customer projects.

- Iterate on UX, data flows and performance based on real-world use.

- Define a clear joint value proposition and outline pricing / commercial models.

Phase 3 – Go-To-Market

- Package the outcome as a commercial joint offering (branding and positioning to be agreed).

- Extend to additional vessels, trades and fleets.

- Continue R&D on advanced analytics, automation and AI-driven decision support.