Solutions · By Vessel Type

Gas Carrier Operations with SecureLoad

Who Uses SecureLoad on Gas Carriers

On the ship

Masters

Make loading and ballast decisions with clear visibility of stability, strength and key constraints for each condition.

Chief Officers

Prepare and adjust loading and ballast plans without juggling separate spreadsheets, while keeping within tight gas carrier envelopes.

On shore

Marine / Fleet Superintendents

Review and support vessel conditions, ensuring company rules and safety margins are applied consistently across the fleet.

Technical / HSSE Managers

Define and monitor technical and safety standards for loading, ballast and stress, and see how they’re followed in practice.

Operations / Scheduling / Cargo Planners

Test proposed parcel patterns and voyages against real vessel capabilities before committing, using a shared technical picture with the ship.

Gas Carrier Realities We Design For

Onboard & Voyage Planning

- Managing multiple tanks, grades and temperature states, with cooldown/warming constraints and tight operating windows.

- Keeping every condition within strict stability, longitudinal strength, draft and trim envelopes.

- Handling last-minute parcel or sequence changes without losing control of margins or constraints.

Shore & Fleet

- Seeing the true loadability of each vessel and voyage—not just rough estimates in spreadsheets.

- Standardising how conditions, limits and special constraints are applied across the gas carrier fleet.

- Producing clear, defensible documentation for charterers, vetting teams and external audits.

How SecureLoad Supports Gas Carrier Work

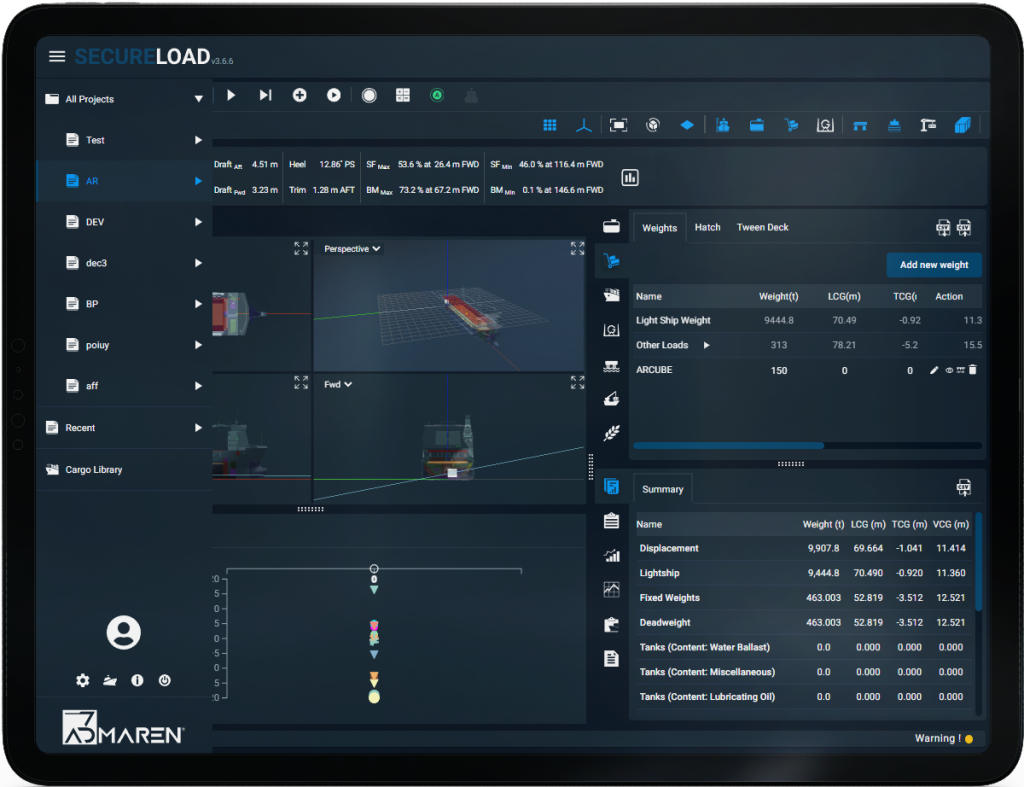

Loading Computer

Ballast & Execution (Workflows)

Fleet Cargo Planner

From Loading Plan to Executed Voyage

Prepare Loading & Ballast Conditions

Run Stability & Strength Checks

Agree Conditions Ship↔Shore

Execute Within Approved Envelope

What Changes With SecureLoad on Gas Carriers

Before SecureLoad

Different practices and spreadsheets on each vessel, even for similar trades and ship types.

Limited visibility for superintendents into how limits and special constraints are actually applied.

Extra work to assemble consistent, defensible documentation for charterers, vetting and audits.

With SecureLoad

A shared, validated workflow for gas carrier loadcases and ballast plans across the fleet.

Clear margins and constraints that ship and shore interpret the same way on every condition.

Consistent, exportable reports that support vetting, charterer dialogue and audit discussions without rework.

Standardise How Your Gas Fleet Plans and Loads

Common templates and rule sets

Use shared loadcase templates and rule sets per gas carrier class, so similar vessels are always engineered the same way.

Aligned structure for operating conditions

Apply consistent naming and structure for typical loading, loaded passage, cooldown/warming and ballast conditions.

Compare practices across vessels

See how margins and practices differ across vessels, and use that insight to tighten standards or replicate best performers.

Safety, Vetting and Marine Assurance

Transparent view of safety margins for stability and strength on each key condition, not just final snapshots.

Repeatable documentation packages for vetting, SIRE/inspections and internal marine assurance, built from the same workflow every time.

Historical loading cases retained for review after incidents or near-misses, supporting fact-based learning and improvement.

Typical outputs

- Condition summaries for loading, loaded passage and ballast cases

- Stability and longitudinal strength check overviews

- PDF / print-ready reports for ship, shore and vetting files

Resources for Gas Carrier Teams

Deep-dive into how SecureLoad works in real operations.

Blog

Ship↔Shore Continuity for Gas Carrier Load Planning

How a shared loading workflow and common margins between ship and shore reduce risk and rework on pressurised and refrigerated gas trades.

Videos

Gas Carrier Loading Workflow in SecureLoad – Short Demo

Watch a sample gas carrier case from loading plan to executed voyage, with shared visibility for ship and shore teams.

Downloads

Loading Computer for Gas Carriers – One-Pager

A quick overview of how SecureLoad supports gas carrier stability, strength and ballast planning in one workflow.