Solutions · By Vessel Type

Heavy-Load Barges with SecureLoad

Who Uses SecureLoad on Heavy-Load Barges

Onboard / Afloat

Barge Masters / Captains

Sail with clear, validated barge conditions—trim, stability and seafastening—documented for each stage of the tow.

Supervising Officers / Marine Reps

Oversee loading, ballasting and seafastening on site with access to agreed scenarios and limits, not just static drawings.

On shore

Heavy Transport / Project Engineers

Design and verify barge stows, ballasting plans and seafastening based on real barge geometry and loadcases.

Port Captains / Superintendents

Coordinate operations at load-out, float-off and intermediate ports, checking that changes stay within agreed margins.

Marine Warranty / HSEQ Teams

Review transparent calculations, scenarios and documentation packages that link directly to how the barge is planned and operated.

Operational Realities on Heavy-Load Barges

Planning & Engineering

- Large, tall or uneven units with strict CoG, support and load-spread requirements on limited deck area.

- Tight trim, draft and under-keel clearance constraints in shallow or restricted waters.

- Multiple barge conditions to plan and check—harbour, restricted waters, open sea, load-out and float-off.

Execution & Assurance

- Proving feasibility to clients, MWS and class with calculations and assumptions that are fully traceable.

- Managing ballast through the voyage to keep the barge within agreed envelopes for trim, draft and stability.

- Coordinating changes in cargo, routing or weather windows without having to rebuild plans from scratch each time.

How SecureLoad Supports Heavy-Load Barges

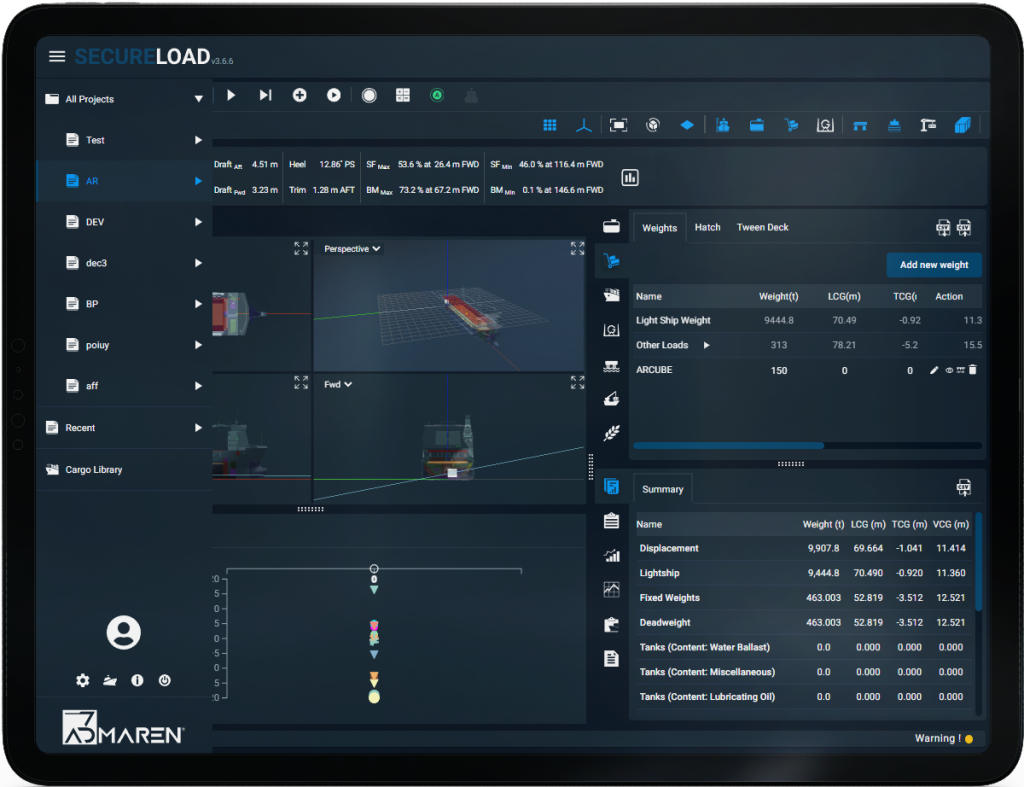

3D Stowage Planner

Acceleration & 3D Lashing

Loading Computer / Ballast & Trim

From Feasibility Check to Tow-Out

Define Cargo & Support Layout

Design Stowage in 3D

Run Lashing & Motion Cases

Evaluate Stability, Strength & Envelopes

Produce Approval Package

What Changes With SecureLoad on Barges

Before SecureLoad

Multiple disjointed tools – CAD models, spreadsheets and separate lashing calculators for each project.

Difficulty keeping a single “approved” version as cargo, ballast or routing changes.

Time-consuming back-and-forth with MWS and clients over assumptions, envelopes and safety margins.

With SecureLoad

3D stow, lashing and loading checks all linked to the same barge and cargo data.

Clear versioning from initial feasibility through revisions to final approved tow-out case.

A documentation package designed to answer the questions MWS, class and clients actually ask.

Managing Trim, Draft and Clearances

Evaluate draft and trim across key conditions

Check draft and trim for different loading, towing and harbour conditions so you know where the barge sits in each phase.

Respect under-keel clearance in shallow waters

Consider under-keel constraints for shallow channels, rivers and ports, with visibility on margins at critical locations.

Plan practical ballast strategies

Define ballast strategies that keep the barge within agreed envelopes for trim, draft and stability throughout the voyage.

Supporting Multi-Barge and Campaign Projects

Use shared vessel and cargo libraries across multiple barges in your fleet or partner pool.

Reuse successful stow, ballast and lashing patterns for similar modules instead of starting from a blank page.

Build up a history of engineered cases that inform internal standards and speed up future approvals.

Resources for Heavy-Load Barge Teams

Deep-dive into how SecureLoad works in real operations.

Blog

Planning Heavy-Load Barge Transports with Confidence

Why tight trim, shallow water and complex modules demand a single engineered view of stowage, ballast and seafastening.

Videos

Heavy-Load Barge Case in SecureLoad – Short Demo

Watch a sample barge project from feasibility to tow-out, using 3D stowage, lashing and ballast workflows.

Downloads

Heavy-Load Barge Planning with SecureLoad – One-Pager

A concise overview of how SecureLoad supports stowage, lashing and loading checks for heavy-load barge projects.